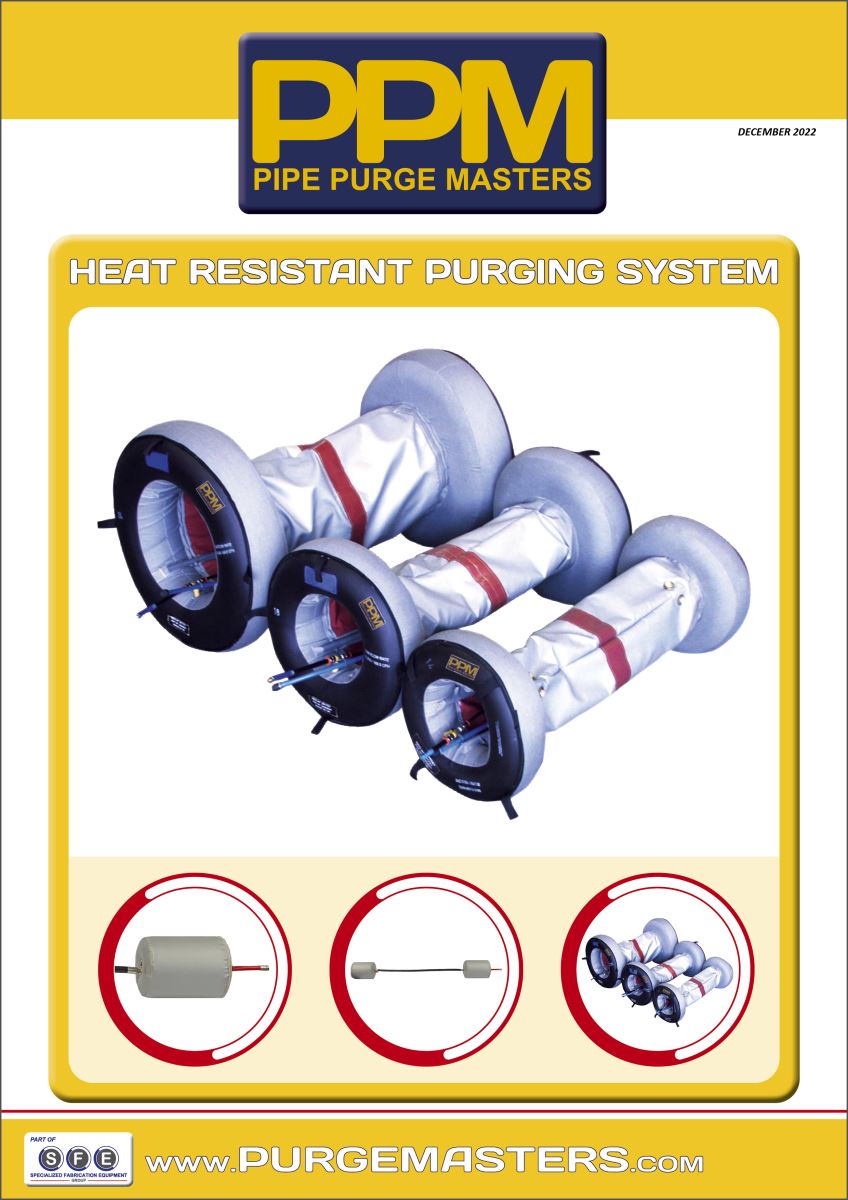

HEAT RESISTANT PURGING SYSTEMS

Sizes: 3" - 80" (63 mm - 2,044 mm)

Systems for the fast purging of high temperature pipework

The PPM Purge Bag and Rapid Purge™ systems are both available in heat resistant version. They are designed to use when high temperatures will be encountered during the process of pipe welding; such as pre-heated pipework, and pipes where very high temperatures are required for welding.

These versions of the inflatable pipe purging systems are heat resistant up to 350ºC (662ºF) for up to 24 hours, or up to 500ºC (932ºF) for short periods of time. The heat resistant systems are available for all pipe diameters from 3" - 80" (63 - 2,035 mm).

Mirroring the features of the standard range of inflatable purging systems, the heat resistant range comes with a central luminous band for rapid centering of the system to the weld root.

The welder can position these systems prior to pre-heating and leave them in place throughout the pre-heating, welding and post-heat treatment cycles, allowing the weld to be purged continuously for up to 24 hours if necessary.

Features and advantages

- Heat resistant up to 350ºC (662ºF) for up to 24 hours, or up to 500ºC (932ºF) for short periods

- Available for all pipe diameters from 3" to 80" (63 to 2,044 mm)

- Designed to be flexible, for ease of insertion, use and withdrawal from pipes, bends, elbows etc.

- Suitable for 24 hour cycles including pre-heat, welding and post-weld heat treatment

- A central luminous strip allows fast and accurate alignment of the system to the center-point of the weld area

- Manufactured to nuclear quality standards with nuclear approved materials, these systems guarantee bright, shiny, coke and oxide-free welds

- Designed and manufactured specifically for the power industry where high strength chrome alloy steels are more frequently used

- Ready to use, connects to a dedicated and regulated gas supply.

- Choose any flow rate (purge bags - up to 20l/min/Rapid Purge™ up to 80l/min) through the twin pre-set purge valve