WHY PURGE?

When welding stainless steel, titanium and other corrosion resistant materials, the perfect environment for welding is paramount to maintaining the corrosion resistant properties.

During the welding process, the weld seam is subjected to heat and air, which can cause oxidation, if the correct processes are not adhered to.

For the best results, oxidation must be prevented.

The quality of the exotic corrosion resistant material welding is dependent on the correct purging methods to minimize or eliminate oxidation.

All PPM (Pipe Purge Masters) purging systems are designed to efficiently remove oxygen as fast as possible.

This can be achieved by isolating the smallest area of pipe, resulting in the fastest purge times, while also minimising the amount of purge gas used.

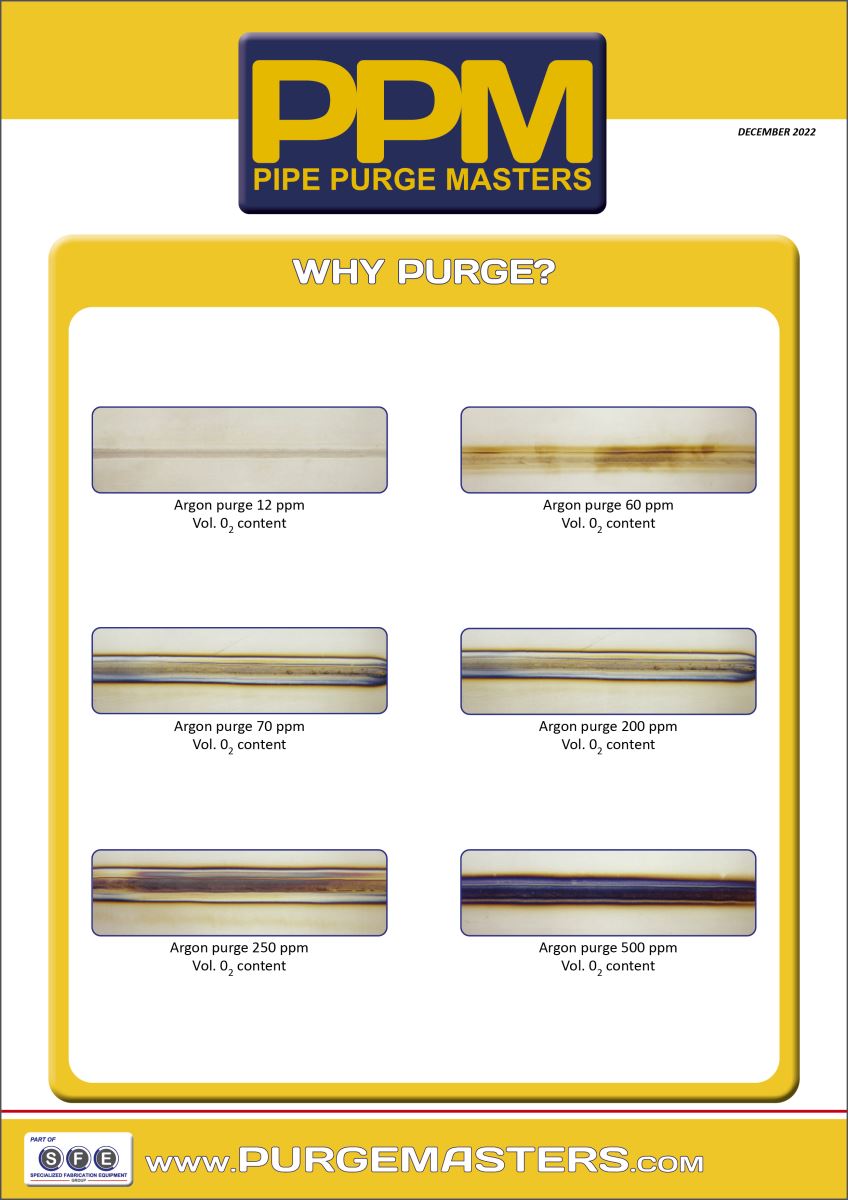

WELD QUALITY

The effective welding of stainless steel, titanium and other exotic materials for the nuclear, petrochemical, pharmaceutical, semi-conductor, aerospace and food industries requires the proper tools to create a perfect weld environment.

Purging equipment and its use have a major impact on preventing oxidation and improving final weld quality. The basic principles of purging can be seen below.

PPM supplies a comprehensive range of systems to create the correct welding environment, whatever the application.